Notices

2024-04-05

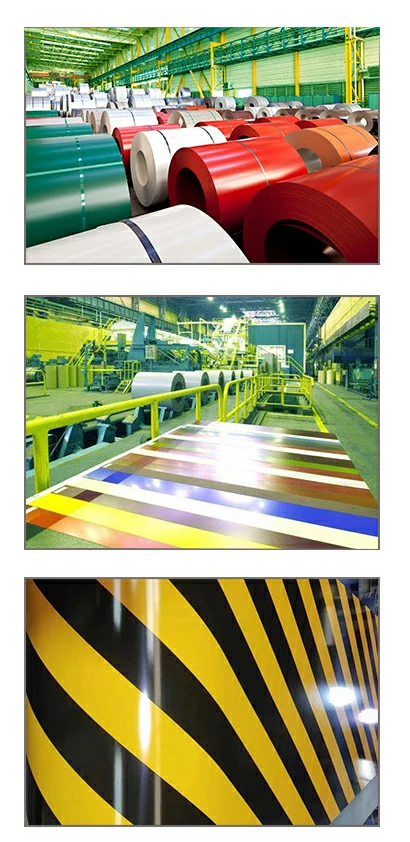

PPGI, PPGL, PPAL- Steel Coil

Keyword:

Categories:

Why you can trust zida steel ? ? ?

1. Payment : 0 Deposit .

2. Delivery time : 10 days for stock .

3.Quality Inspection : SGS

4. Price : Good Price

5. Reliable brand : zida steel

6. Beat your competitors

Join in and be partner of zida

Description

|

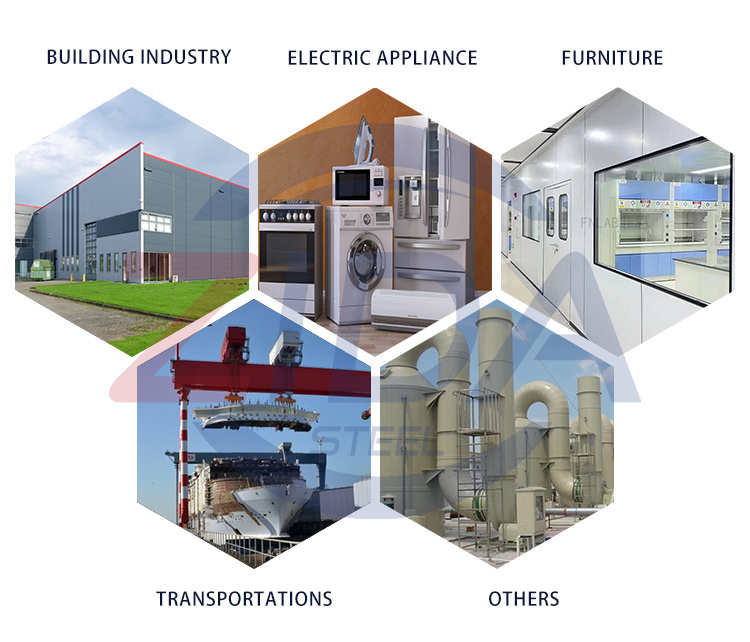

COLOR COATED STEEL COIL - PPGI, PPGL, PPAL PROFESSINOAL TEAM ON-TIME DELICERY ADEQUATE STOCK

|

|

| Our PPGI(Prepainted Galvanized Steel) & PPGL (Prepainted Galvalume Steel) & PPAL (Prepainted Aluminum Steel) are available in a variety of specifications. We could also provide the product life length lasts for decades as customers required. The properties of Color Coated Steel are tough coating, completed protection, low maintenance and long life. Pre-painted Galvanized(GI) / Galvalume(GL) / Aluminum(AL) Steel combines utility with beauty. It consists of tin, chrome, zinc or paint, which are the extra finish applied to the natural steel surface. The application of coating is to protect the surface of steel from oxidation and it is also used to enhance requirements for visual appearance.

Color coated plate is also called coated plate, color steel plate, it is based on metal coil (cold rolled plate, hot galvanized plate, aluminum plate, high aluminum |

|

| “PRODUCT INTRODUCTION OF PPGI, PPGL, PPAL:

|

|

|

|

| Characteristics of PPGI: | |

|

First, Material Properties PPGI is a common cold-rolled steel plate as the base material, after surface treatment, and then with color coating or galvanized processing process of architectural decoration materials. Its main features include: Second, Construction Use 1. Convenient construction: PPGI is easy to install, lighter than traditional tile, stone, glass and other decorative materials, reducing the labor intensity of workers and improving construction efficiency; Third, Environmental Sustainability 1. No harmful chemicals are used on the internal and external surfaces, and the test is qualified; Conclusion In summary, galvanized color plate has the characteristics of anti-corrosion, weather resistance, good decoration, easy construction, long service life, and environmental sustainability, is an excellent building decoration material. |

|

| Difference Between PPGI and PPGL: | |

|

PPGI and PPGL are two different coating technologies, and there are some differences in application and performance. PPGI is a technology in which GI is coated with a layer of color pigment on the surface of GI, which is suitable for lighter environmental conditions. The advantage of PPGI is its variety of colors, which can be adjusted as needed, and its lower price. However, PPGI color pigments can only provide limited corrosion resistance, in harsh environmental conditions, the color may fade, and do not provide good corrosion resistance. The advantage of PPGL is that its aluminum zinc has good corrosion resistance and electrical conductivity, and can effectively resist acid, alkali, salt and other corrosion factors. PPGL's color pigments have better corrosion resistance and do not fade easily. However, PPGL's price is relatively high. Therefore, when choosing PPGI and PPGL, it is necessary to consider the location of use, environmental conditions and customer needs. If you need to use in light environmental conditions, color requirements are high, and price sensitive, then PPGI is a good choice. However, if you need to use in harsh environmental conditions and need to provide good corrosion resistance, then PPGL is a better choice. In the production process of PPGI and PPGL, there are also certain differences. The production process of PPGI is relatively simple, the process is not complicated, and the production cycle is short. The production process of PPGL is complicated, the process is cumbersome and the production cycle is long. Finally, it should be noted that the value and cost performance of PPGI and PPGL are different, and customers need to weigh the pros and cons according to their needs when choosing to ensure that the most appropriate coating technology is selected. In short, PPGI and PPGL are two different coating technologies that differ in application and performance. Which coating technology to use depends on the place of use, environmental conditions and customer needs. |

|

| Product Type: | |

| The colour coated coil colors are mainly divided into Solid Colors and Printed Patterns. And both are customizable. 1. Solid Color (Smooth surface or wrinkled surface) You can choose colors according to RAL Color or you can send us a sample. The popular colors include Sea Blue, Grey, Ivory, White, Brick Rred, Porcelain Blue, Grass Green, Silver, Leaf Green, Orange, etc. 2. Printed Pattern The popular patterns of ZIDA STEEL products include Flower, Grass, Camouflage Pattern, Wood Grain, Marble Grain, Brick Grain, Stone Grain, etc. We can also customize the pattern according to your samples. |

|

|

|

| Product Parameter: | |

| Color-coated Coil Coating Type: |

|

The strength of the color steel plate depends on the substrate material and thickness, and the durability depends on the coating, surface coating and processing technology, and the coating has polyester coating (PE), fluorocarbon coating (PVDF), silicon modified coating (SMP), high weather resistant coating (HDP), acrylic acid coating, polyurethane coating (PU), plastisol coating (PVC) and so on. The coating structure has two coating and one drying, two coating and two drying, etc., and the maintenance-free service life can be 10-30 years according to the different environment and atmosphere. |

| Paint distinction: |

| Environmental Conditions: |

|

1. Environmental factors of corrosion Longitude and latitude, temperature, humidity, total radiation (UV intensity, sunshine duration), rainfall, pH, wind speed, wind direction, corrosive fallout (C1, SO2). 2. The influence of sunlight Sunlight is an electromagnetic wave, according to the energy and frequency of the high and low divided into gamma rays, X-rays, ultraviolet, visible light, infrared, microwave and radio waves. Among them, the ultraviolet spectrum (UV) is a high-frequency ray, which has a greater destructive power than the low-energy spectrum, such as the skin spots we know are caused by the sun's ultraviolet rays. UV can also break the chemical bonds of a substance, causing it to break, depending on the wavelength of the UV and the strength of the chemical bonds of the substance. X-rays have a penetrating effect, and gamma rays can break chemical bonds and produce free charged ions, which are deadly to organic matter. 3. the influence of temperature and humidity For metal coatings, high temperature and high humidity contribute to oxidation reaction (corrosion). When the color coated board is in high temperature environment for a long time, the paint molecular structure on the surface of the color coated board is easy to be damaged, which affects the service cycle. When the humidity is high, the surface of the plate is easy to condensation, and the trend of electrochemical corrosion is enhanced. 4. the impact of pH on corrosion performance For metal coatings (zinc or aluminum), they are all amphoteric metals, and strong acids and bases can corrode them. However, different metal acid and alkali resistance has its own characteristics, galvanized plate alkaline resistance is slightly stronger, aluminum zinc acid resistance is slightly stronger. 5. The impact of rain The corrosion resistance of rain to color coated panels depends on the structure of the building and the acidity of the rain. For buildings with large slopes (such as walls), rainwater has a self-cleaning function to prevent further corrosion, but if the injection molding slope is small (such as roofing), rainwater will be deposited on the surface for a long time, promoting the hydrolysis of the coating and water penetration. For the joints or cuts of the steel plate, the presence of water increases the possibility of electrochemical corrosion, and the orientation is also important, and the acid rain situation is more serious. |

| Product Features: |

|

1. Excellent Corrosion Resistance Due to the 55% of aluminum, the resistance to corrosion of PPGL is much better than PPGI’s, which can greatly prolong the service life. 2. Great Heat Reflectivity The good heat resistance can keep the buildings cool in the hot summer. 3. Weather Resistant Excellent Pre-painted galvalume steel can withstand harsh weather conditions such as extreme summers, winters, or rainfall. 4. Good Processing Performance The PPGL steel sheets from ZIDA Steel are easy to profess, such as shearing, profiling, blanking, etc. 5. Beautiful Appearance They look attractive and impressive with a pleasant surface finish and aesthetics. |

| Product Applications: |

|

Pre-painted Galvanized/Galvalume Steel are used in roof structure, surface sheet of balcony, frame of window, folding screen and electrical equipment. Pre-painted steel can be formed into almost any shape, and it has excellent resistance to weathering, superior longevity and texture options. |

|

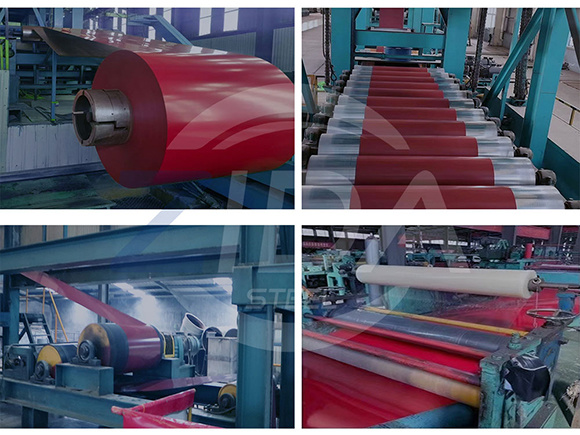

| “ABOUT US:

|

|

|

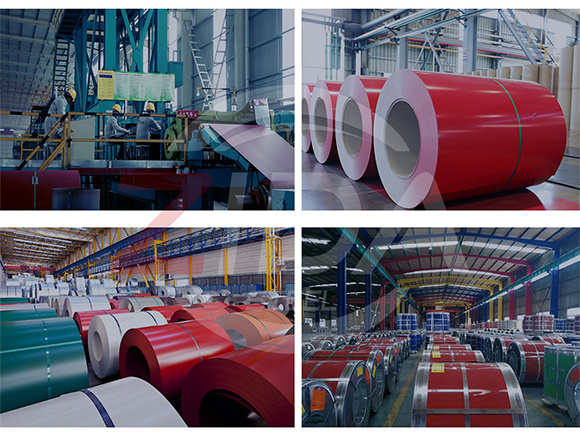

| “MANUFACTURING SHOP :

|

|

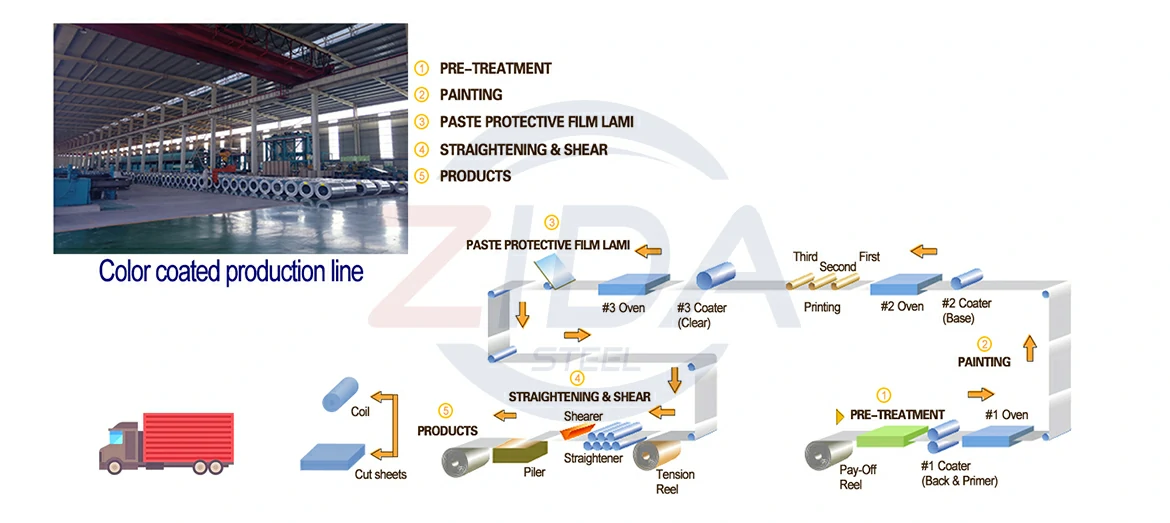

| Production Flow Chart: |

|

|

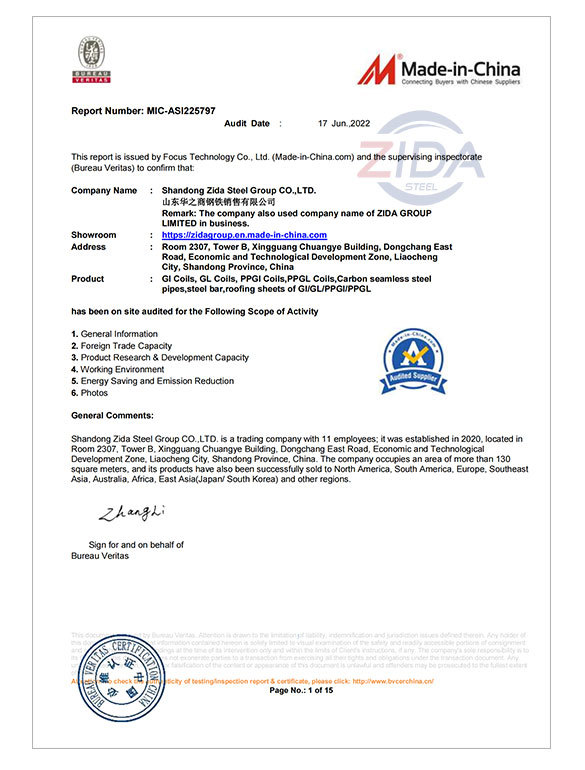

| Quality Control: |

|

| Quality Certificate : |

|

|

| Our Service: |

|

We offer Service For 500+customers ,and our products are sold to over 50+ countries and territories. 1200000 Tons | SGS/COC/POVC | Free Samples | Within 24h | Perfect Service Annual Capacity | Available | A4 Size | Response Time | Professinoal Teams |

Cooperative partner

Shandong Guanzhou Co., Ltd.

HBIS Group Co., Ltd.

Tianjin Pipe Corporation ( TPCO).

Linqing Hongji Group Co.,Ltd.

Hebei Zhaojian Metal Product Co., Ltd.

Shougang Group

Tangshan Donggang Metal Sheet Manufacturing Co., Ltd.

Shandong Panjin Steel Pipe Manufacturing Co., Ltd.

Hubei Xinyegang Steel.Co.,Ltd.

China National Building Material Group Co., Ltd. (CNBM)

Linzhou Fengbao Pipe Industry Co., Ltd.

Boxing Galvanized Steel Sheet Factory.

Exhibitions And Customers

SHANDONG ZIDA STEEL GROUP CO., LTD mainly supplies a variety of materials of Steel Coil, Steel Strip, Steel Plate, Color Coated Steel Coil, Color Coated Steel Plate, Corrugated Steel Plate, Steel Pipe, Profile Steel and Fittings.Our products are mainly divided into five series: Carbon steel series, Galvanized series, Galvalume series, Aluminum series and Stainless steel series.Our products are widely used in construction, light industry, chemical industry, aviation, agriculture, animal husbandry and fishery, commercial, automobile and shipbuilding industries.

Product inquiry